At STEER, we craft both volumetric feeders and side feeders. STEER Feeders assure optimised feeding of the materials ranging from highly cohesive to interlocking fibers. The feeders are known for their noiseless and pollution-free operations. Besides, STEER has also designed conveying elements for high consistency and precise dosing into the extruder.

DESIGN AND FEATURES

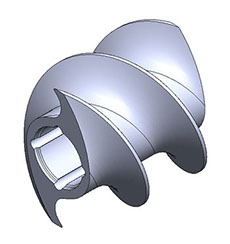

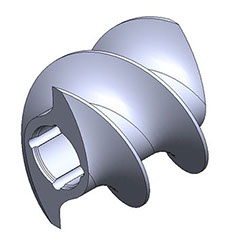

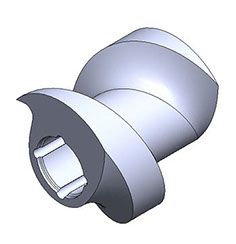

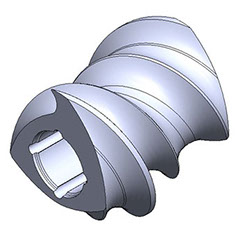

Understanding bulk material is crucial to making an efficient feeder for twin-screw extruders. The screw has to be designed based on the type of bulk material i.e., granular, cohesive powders, fibres or flaky materials. STEER has developed screws that are appropriate for every application. The Hopper, designed on bulk material properties, overcomes defects like rathole and arching.

STEER Side Feeders are designed to feed a variety of materials like glass-fibres, powder additives, mineral fillers etc. Side feeders can also be used for devolatizing applications through side venting. The Side feeder height is adjustable within a range and is portable (by the use of castor wheels). Barrels and screws are of special tool-steel material and suitably surface treated for required applications. The screws are of a co-rotating, self-wiping type and the drive is a 4 pole TEFV, Cage type, AC Motor, controlled by a variable speed microprocessor controlled drive control.