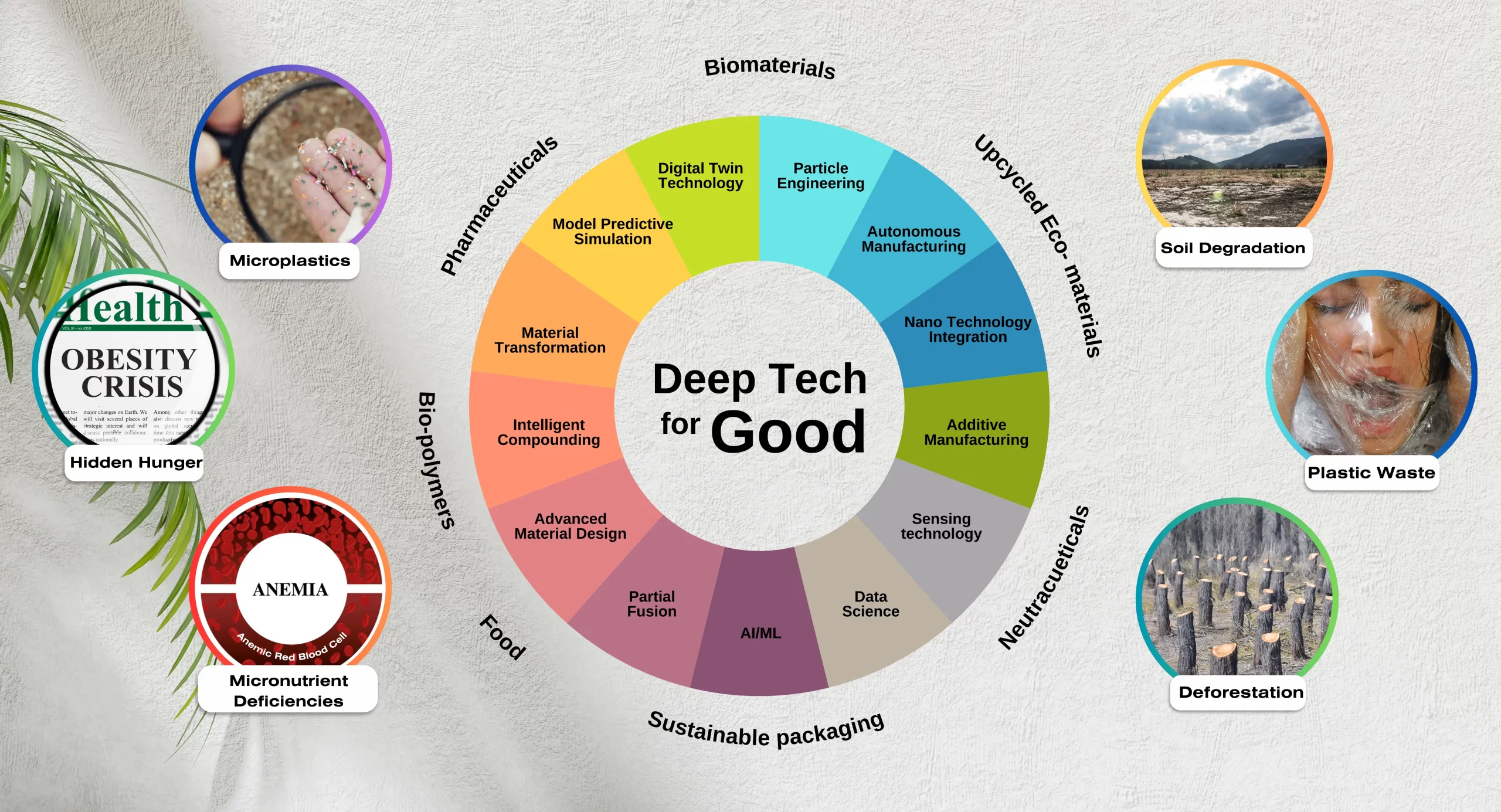

Global Leader in self-cleaning process engineering solutions, specializing in polymer compounding technology, pharmaceutical and food processing with advanced manufacturing. Pioneering advancement in autonomous manufacturing of continuous process.

Transforming lives WITH SCIENCE AND ENGINEERING INNOVATION

STEERING A JOURNEY THROUGH TIME

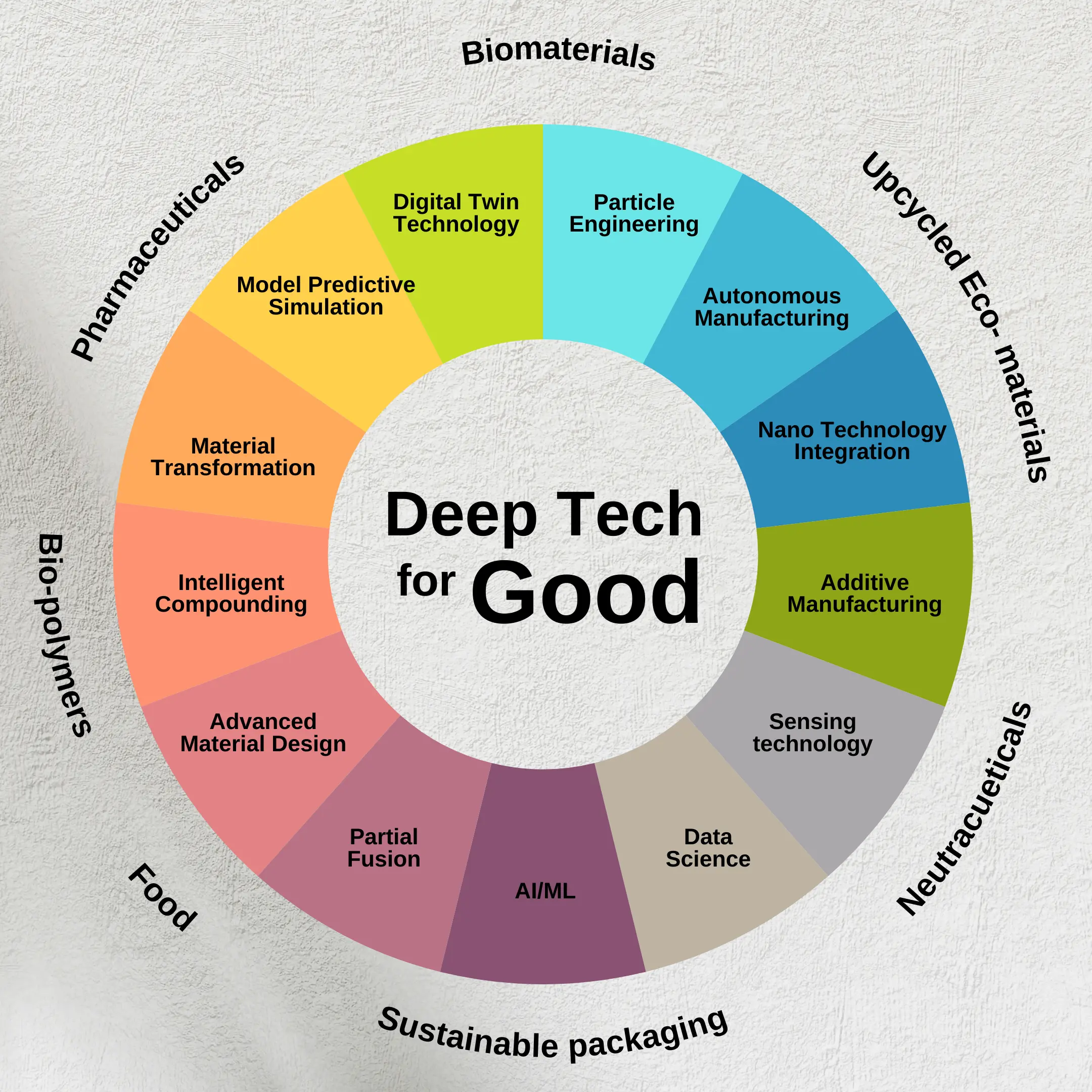

STEER WorldOur Pillars of Innovation

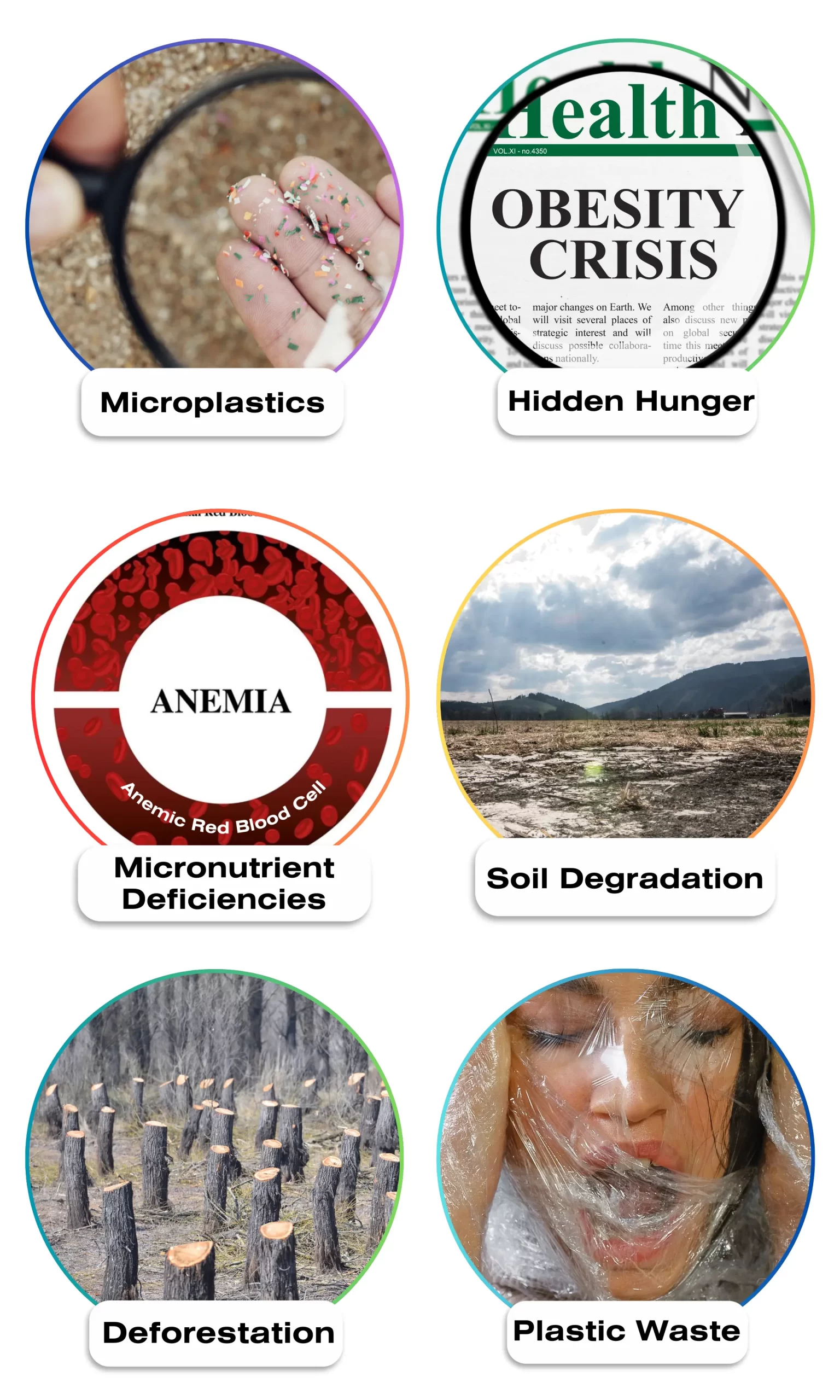

Revolutionary patented machine and technology that can handle commingled, multi-layer packaging waste (ocean bound plastics) at origin and convert to affordable and high-performance substitutes that would replace wood more effectively avoiding deforestation.

Disruptive packaging and with eco and biophilic alternatives. One of a kind, patented sustainable packaging that not only prevents microplastics from affecting our biome but also enriches soil through bio assimilation.

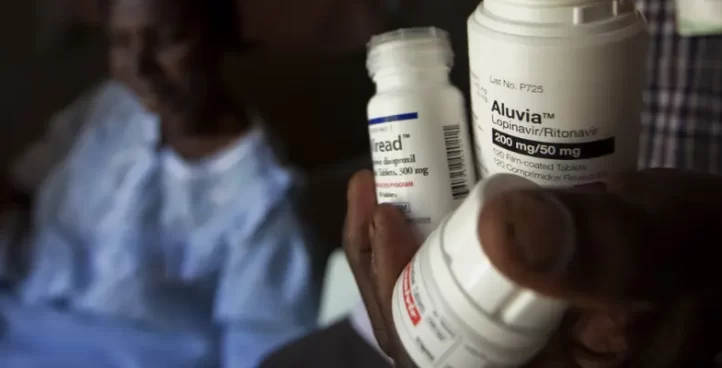

Enhancing the Affordability / Quality of Food and Medicine. Pioneered partial fusion technologies for drug development and ingredient transformation. Affordable anti-viral medicine, iron and calcium supplementation with improved tolerance through increased bio-availability. Staple Foods to address nutrition related life-threatening conditions.

Meeting precision in the realm of advanced metallurgical solutions, leveraging cutting-edge techniques alongside our in-house heat treatment facilities to engineer components built for power and durability. Creating products that surpasses industry standards, delivering unparalleled strength and reliability.

Solving Real World Problems

What we doOur Products & Solutions

Twin Screw Extruder

STEER platforms are a combination of high-performance technology, design thinking and advanced engineering.

READ MOREEPZ Replacement Parts

A good compound is the result of a thorough understanding of what goes on inside the ‘extruder processing zone (EPZ)

READ MORETurnkey Projects

One stop solution for your expansion, to eliminate TSE and Auxiliary equipment performance risk. Advantage of getting process & product. Know how?

READ MOREOurFocus Areas

Powder Coat

The STEER OMEGA POWDER COATING CO-ROTATING TWIN-SCREW EXTRUDER offers enhanced mixing and melting capabilities, excellent value and productivity, and amazing processing experience.

READ MOREBio-Polymers

Process World Class Compounding with World-Class Technology for Sustainable applications

READ MOREConstruction

Steer Engineering achieved this success by processing the material in its Co-Rotating Twin Screw Extruders using a patented Screw Geometry, involving patented wave elements.

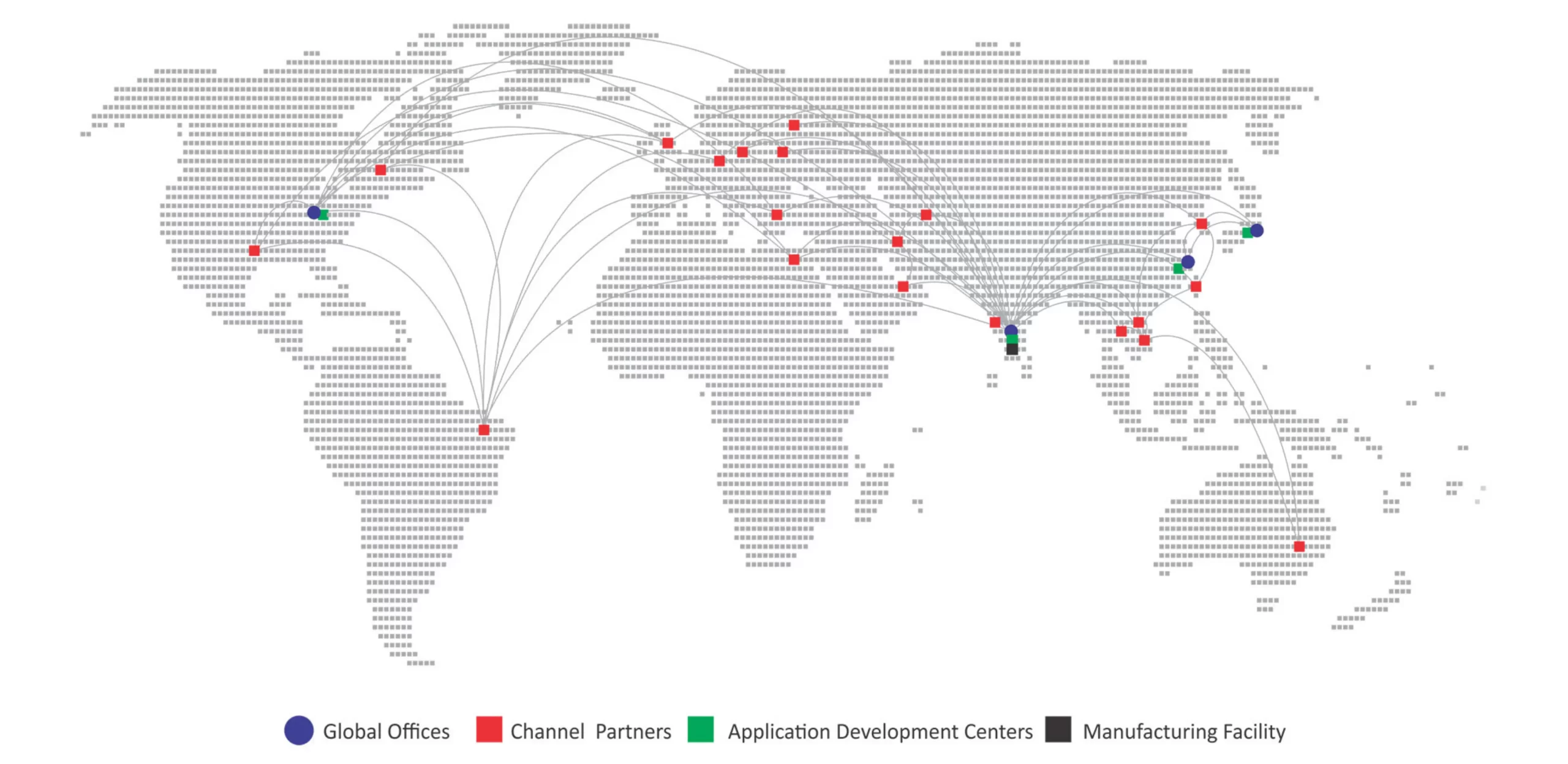

READ MOREOur Global Legacy

Established in 1993. End-to-end Engineering Solutions for Pharmaceuticals & Plastics Manufacturing. One of the earliest Innovators in continuous flow processing technology with 150+ patents.

0

Global Offices

0

Satellite Offices

0

Application Development Centres

0

Patents

0

Countries Served

0

+ Elements Sold

0

+ Employees

0

+ Installations

Our Application Development Centers

Innovation Lab

STEER has 4 state-of-the-art Application Development Centers (ADCs) in India, Japan, China and U.S, as well as a dedicated Polymer Science & Diagnostic centre (PSDC) in India. These centers were specifically set up to collaborate and co-create with partners and customers to develop newer, advanced materials, solutions and methods, besides providing testing, characterization and validation services.

Services & Solutions

STEER ANNUAL MAINTENANCE CONTRACTS

MINIMUM DOWNTIME. MAXIMUM SATISFACTION

STEER undertakes Annual Maintenance Contracts (AMC’s) for extruders to ensure maximum productivity and minimum downtime.

Help lines: +91-9900101510, +91-9900101500 For additional information, write to : service@steerworld.com

RELINING AND REFURBISHING SERVICES

STEER also undertakes the complex task of Barrel relining and Gearbox refurbishing to give your platform an extended life.

News and EventsInsights Hub

Eye on Innovation

In George Bernard Shaw’s Man and Superman, the Devil asks Don Juan why he expends effort to learn about himself and what motivates him. Don Juan replies: “Why, to be able to choose the line of greatest advantage instead of yielding in the direction of the least resistance. And there you have our difference: to be in hell is to drift,

…to be in heaven is to

Steer a New World became the theme of the organization, that if we do not steer and maintain control over our direction, our course will be determined by random events rather than by our goals and aspirations.