We use cookies to enhance your browsing experience, and analyze our traffic. By clicking Accept, you consent to our use of cookies.

Enhanced removal of volatile gases, ensuring higher product purity.

Reduced downtime from vent blockage, maintaining continuous operation.

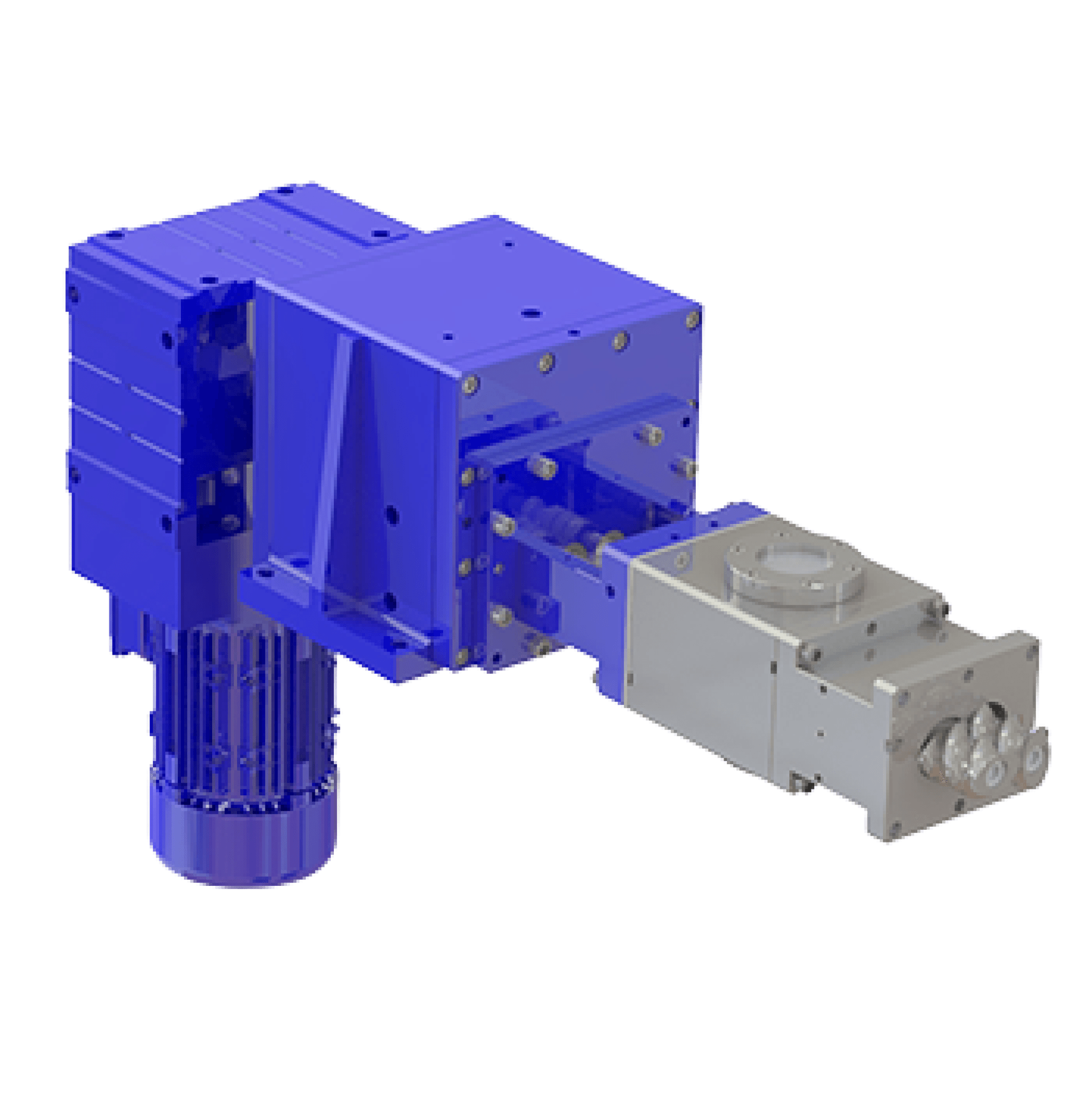

The screws are decoupled from the gearbox via a connecting zone. This enables specialized configuration for tailored processing.

Improved product quality and production rates.

Incorporates high performance gearbox and thrust bearing assemblies to provide high reliability and extended service life.

Get in touch with us to integrate our products into your portfolio to enhance your product business and advance consumer health.