COMPOUNDING

Precision, Performance, Homogenous Mixing and Innovation in Every Batch

STEER’s cutting-edge twin-screw technology revolutionizes the compounding process, offering unmatched quality and value across various applications. From producing high-performance masterbatches to advanced polymer blends and specialized compounds, STEER ensures superior energy efficiency, stability, and adaptability. Our patented technologies address key challenges in compounding, ensuring optimal performance and consistency.

Innovative Compounding Solutions

STEER leads the way in compounding innovation with tailored solutions for advanced applications. Our technology supports a broad range of compounds, from polymer blends and nanocomposites to high-filled fillers and specialized rubber formulations. With STEER, you gain access to cutting-edge capabilities that address the most demanding material requirements and drive forward innovation in your industry.

Benefits

Superior Mixing and Dispersion

Achieve consistent, high-quality compounds with exceptional uniformity and efficiency.

Enhanced Thermal and Mechanical Properties

Maximize material performance with precise control over temperature and processing conditions.

Flexible and Scalable Solutions

Adapt to diverse formulations and production scales with ease.

Improved Process Efficiency

Minimize degradation and energy consumption while maintaining high-quality output.

Polymer Blends and Alloys

STEER’s twin-screw extruders excel in polymer processing, delivering superior performance and versatility. Our technology creates advanced polymer blends and alloys with enhanced mechanical, thermal, and electrical properties for diverse manufacturing needs.

PA Compounding with Short Glass Fibre (SGF)

STEER’s twin-screw extruders excel in PA compounding with short glass fibres, offering superior mixing, precise temperature control, and adaptable processing. Our technology ensures enhanced performance and versatility for high-durability applications.

PA Compounding with Glass Roving

STEER’s twin-screw technology enhances polyamide with glass roving, improving mechanical strength, thermal stability, and dimensional accuracy. Our advanced compounding process ensures high-performance materials for demanding industrial applications.

Nano Compounding of Polyolefins and Engineering Plastics

STEER’s twin-screw technology advances nano compounding for polyolefins and engineering plastics, delivering high-performance materials with superior strength, thermal stability, and versatility, enhancing innovation and competitiveness across various industries.

Carbon nano tubes Compounding in Engineering Plastics

CNT compounding in engineering plastics via STEER twin screw extruders creates high-performance composites with enhanced strength, conductivity, and thermal properties. This innovative process meets modern industrial demands, driving competitiveness across various sectors globally.

HFFR Compounds

STEER twin screw extruders enable efficient HFFR compound production, enhancing fire safety in polymers. This technology delivers flame retardancy, low smoke emission, and superior properties, meeting global safety standards while ensuring environmental sustainability across diverse applications.

Highly Filled Filler Compounds

STEER’s twin-screw technology enables high-performance filler compounds with enhanced strength, thermal stability, and electrical conductivity. Our precise extrusion process delivers customized, cost-efficient solutions for diverse industrial applications, boosting global competitiveness.

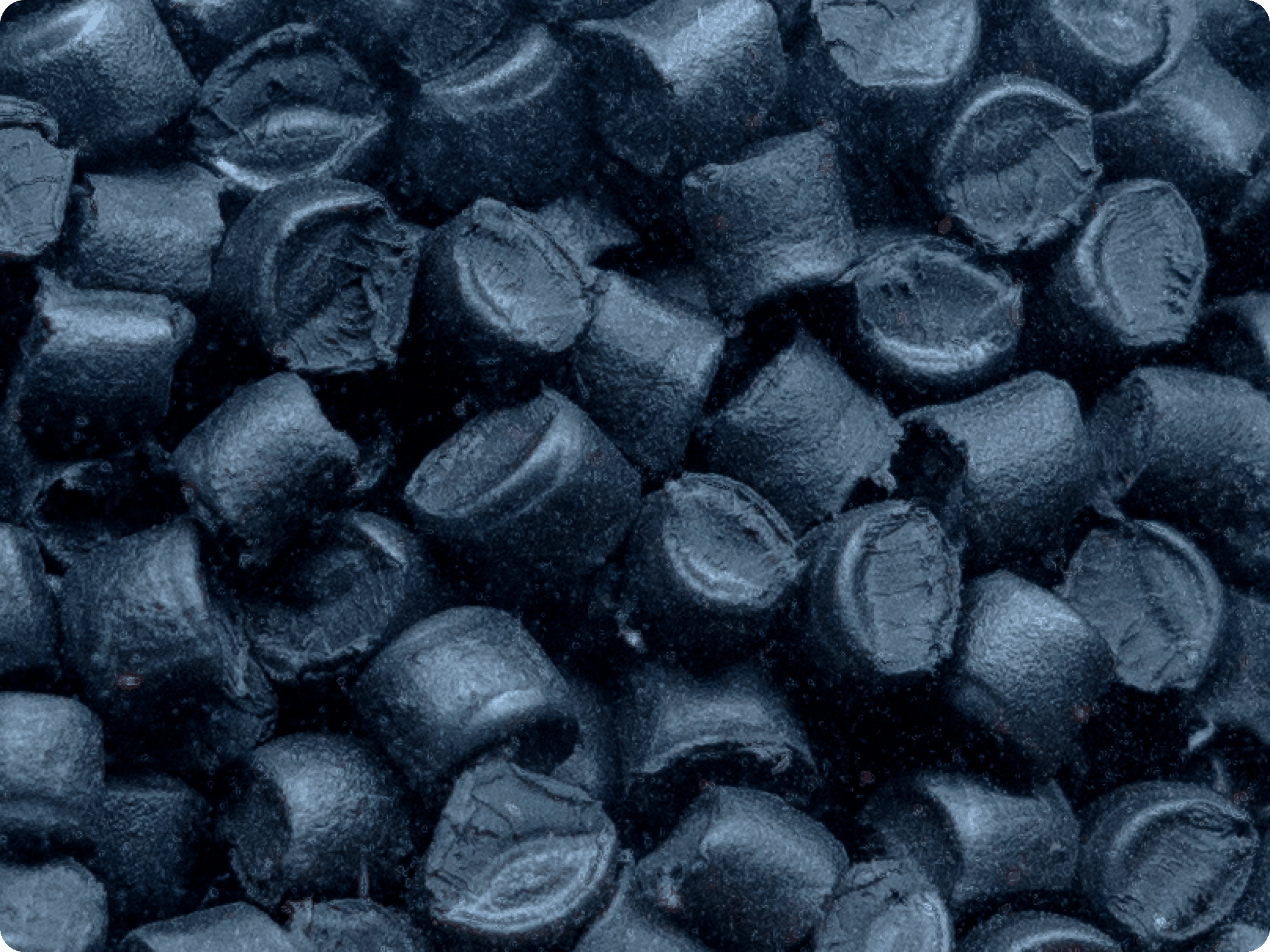

XLPE Compounding

STEER twin screw extruders produce high-purity XLPE cable compounds, utilizing peroxide for uniform cross-linking of polyethylene. This advanced process yields pellets ideal for high and extra-high voltage applications, ensuring superior performance in demanding electrical environments.

Inline Rubber Compounding

STEER's innovation in direct rubber compounding from bales improves processing efficiency and product quality. Our new feeder eliminates the need for granulators, enhancing uniformity and sustainability while reducing energy use and waste.

TPE/TPR/TPO

Thermoplastic Elastomers (TPE), Thermoplastic Rubber (TPR), and Thermoplastic Polyolefin (TPO) are versatile materials blending rubber's flexibility with thermoplastics' ease of processing. Their exceptional durability, weather resistance, and customization make them ideal for diverse industrial applications.

New Idea, New Product

STEER's twin-screw extruder technology opens doors to enhanced productivity, improved product quality, and increased sustainability in the food manufacturing sector.